Target Field

Project Overview

Project Details

VISION

Baseball games aren’t governed by a clock, but baseball seasons are. So when the Minnesota Twins engaged Alpha to upgrade the AV control room and production facility at Target Field, we knew the timeline would be fixed. What no one expected, however, was that the stadium would be selected to host the 2022 NHL Winter Classic on January 1st. Since this event required a fully functioning control room, Alpha had to delay the teardown of the existing facility – shortening the installation window from 12 weeks to 4-6 weeks. “Plenty of integrators would have said, ‘No can do,’” says Jeff Volk, Alpha’s VP of sports & entertainment. But Alpha had more than a few assets in its favor, including the crew that built Target Field’s original control room; the trust of a team that Alpha had worked with since the Twins played in the Metrodome; and a culture of collaboration that routinely says yes to the seemingly impossible.

EXPERIENCE

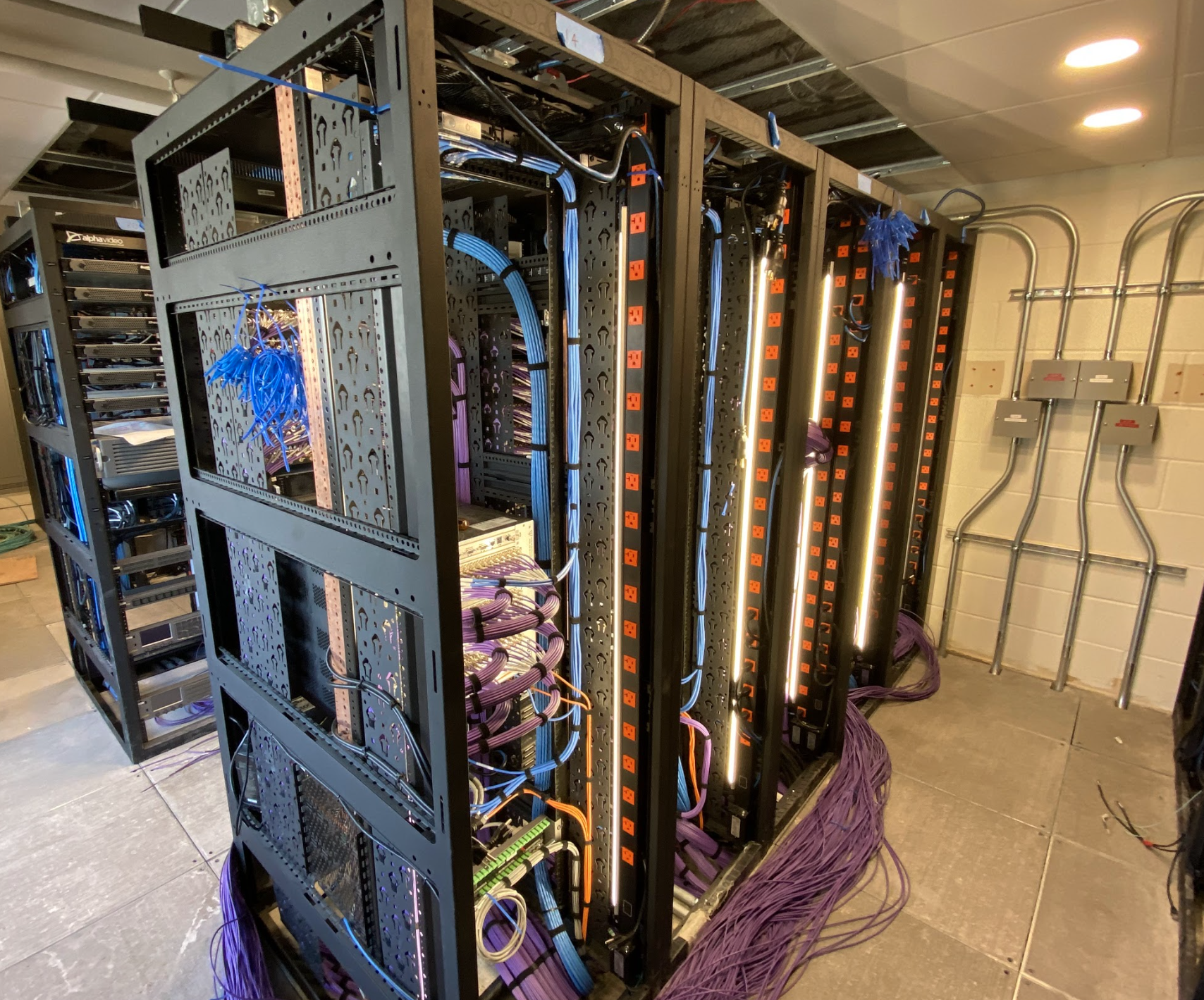

“Completing this project on time meant we had to get creative about how we handled things,” says Volk. “Normally we’d have torn down the existing control room immediately after the end of the 2021 season, but with the New Year’s Day event, the demo wasn’t even complete until mid-January. We had, at best, a month-and-a-half for the principal integration.” To compensate, Alpha prebuilt the control room to a far greater degree of readiness than is customary. Initial staff training was moved from onsite to Alpha’s staging facility while the system was still being built. Alpha also mobilized additional locations for concurrent construction and training. In addition, Volk’s team partnered closely with Mortenson, the general contractor, and HGA, the stadium architects, to map out all the space necessary for people and equipment as part of the physical redesign of the control room.

POSSIBLE

Well-honed logistics. Flexibility built into planning. Strong relationships among partners. They all contributed to results that so pleased the Minnesota Twins that the team subsequently selected Alpha to redesign and build the LED front end for a complete overhaul of Target Field’s scoreboards and video boards. “Great work is never achieved in a vacuum,” says Volk. “Without the trust of the Twins and the collaboration of partners like Mortenson, HKG and numerous sub-contractors, we couldn’t have met the deadline or provided a quality of work that won raves from the team and its owners.” But for Volk, the biggest takeaway from this project was the power of teamwork and accountability. “Between engineering, project management, our business office, sales and field teams, success depends on how well you work together when the surprises happen and the odds stack against you. That’s the kind of commitment you need to hit it out of the park.”